- UL 110

Ensuring Mobile Phones are Sustainable

UL 110 helps reduce electronic waste, or e-waste, from mobile phones by providing manufacturers with guidelines for sustainable practices that can be applied throughout a device’s life cycle.

Abstract

Your cellphone is undoubtedly an invaluable technology that sees hours of use every day. The overwhelming majority of people in the United States have a cellphone, with billions of devices currently in use daily. Once these devices reach their end of life, many of them are not disposed of in an environmentally conscious way. UL 110, the Standard for Sustainability for Mobile Phones, is a comprehensive sustainability standard that addresses many of these concerns by providing a set of required and optional criteria that manufacturers can use to reduce e-waste and environmental damage. The standard offers two levels of certification, incentivizing manufacturers to increase their corporate sustainability efforts by providing them with verifiable sustainability credentials that can be shared with customers. This case study highlights the role of sustainability thinking in engineering and multidisciplinary specialties to ensure e-waste is minimized in consumer electronics — helping create a more circular economy around cellphones.

Learning Objectives

- Understand how safety and sustainability standards ensure transparent environmental responsibility for mobile phone producers

- Explore metrics found within UL 110, the Standard for Sustainability for Mobile Phones, that give manufacturers of mobile phones certifications in sustainability

- Learn how a diverse technical committee is committed to creating criteria for manufacturers to be transparent about their sustainability efforts

Real world context

Mobile phones are critical technological powerhouses for billions of people worldwide, powering learning, communication, business, and more — you may even be reading this case study on one right now.

But there are risks

Improper phone disposal can create dangerous e-waste, leaching metals into ecosystems, causing environmental damage, and negatively impacting human health.

For example

People who eat rice and fish in e-waste recycling areas have experienced elevated levels of mercury exposure, which can damage the nervous system and other systems in the body.

With so many mobile phones being created and discarded daily, what sustainable solutions exist to keep these devices from ending up as e-waste?

Background

People around the world have integrated technologies such as smartphones into their everyday lives so fully that they cannot comprehend living without them. Based on a survey conducted by Pew Research in 2023, 97% of Americans own a cellphone, with 90% owning an internet-connected smartphone, and that number reaches 97% when looking at Americans between 19 and 27 years old. This number has greatly increased from 35% of respondents in 2011. 1

Americans replace their smartphone once every 2-3 years on average, with a recent report from Statista citing a lifespan at around 2.6 years.2 Billions of mobile devices are discarded annually. According to the International Forum on Waste Electrical and Electronic Equipment,3 in 2022, 5.3 billion phones worldwide were expected to become waste.

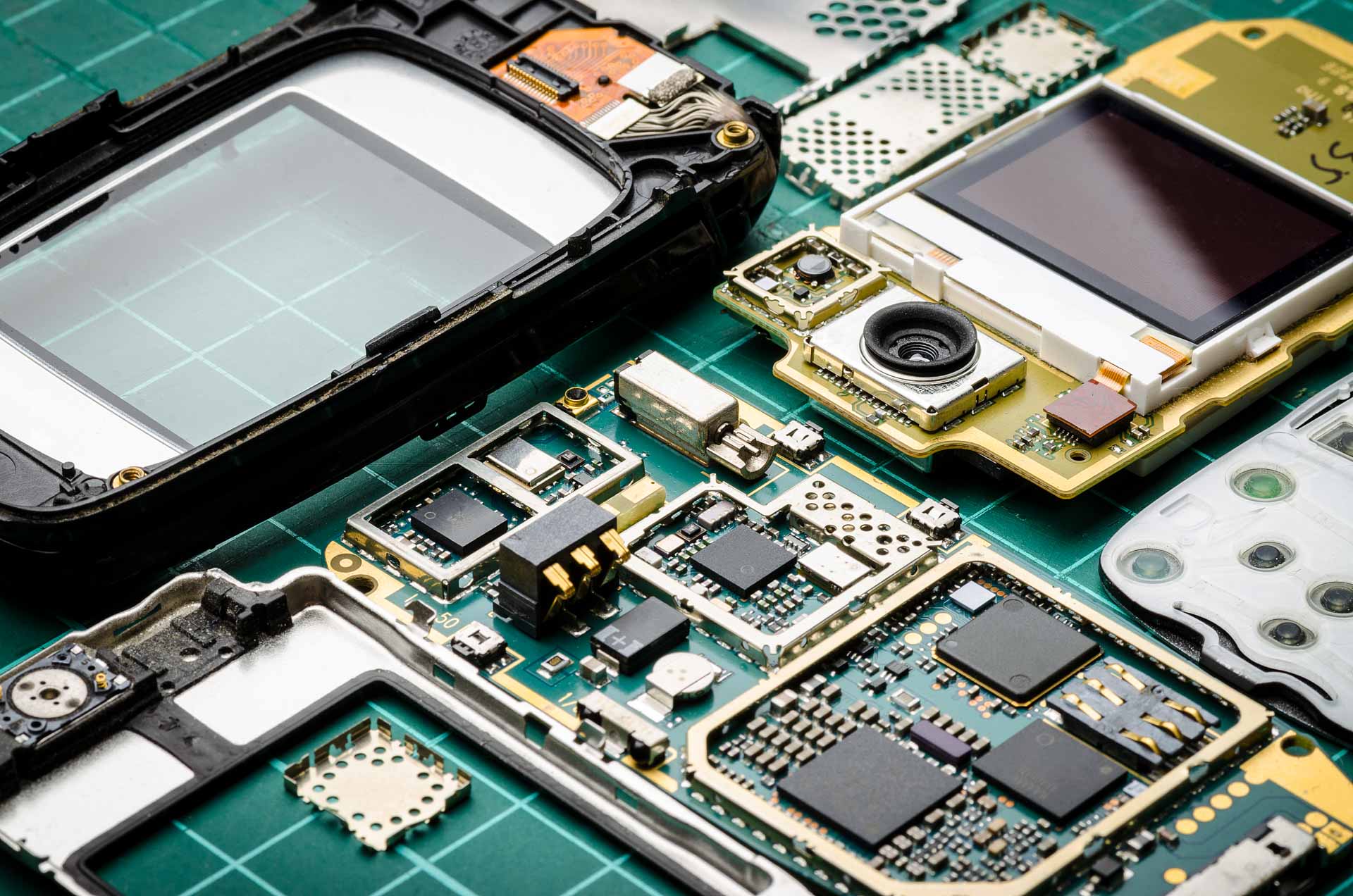

Most often, a mobile device’s life begins in a mine, where raw materials such as lithium, cobalt, copper, and aluminum are extracted, often at heavy environmental detriment. Once extracted, these raw materials are transferred to refining factories and become batteries, wires, circuitry, and other components of mobile phones. These components will then be transferred to a manufacturing factory where they will be assembled into complete mobile phones. This process is already environmentally taxing — an estimated 146 million tons of carbon dioxide emissions are released yearly through the manufacturing process of the world’s cellular phones and smartphones.4

At the opposite end of their life cycle, these mobile devices (and many other devices that contribute to e-waste) may enter a landfill, where they can leach highly toxic material (arsenic, lead, mercury, and more) into groundwater, disrupting ecosystems and communities.5 Recycling e-waste is a promising alternative, as promoted by the Be Nice to Your Device public safety campaign from ULRI’s Electrochemical Safety Research Institute; however, more than 80% of e-waste is not currently being recycled properly.6 As of 2024, 25 U.S. states (and the District of Columbia) currently have e-waste recycling laws, but the results of enforcement have been mixed.7

Recycling is just one piece of the puzzle on increasing sustainability of mobile phones, where consumers and producers need to consider many factors, including repairability of phones, packaging, end-of-life programs, corporate responsibilities, and responsible use of raw materials. The life cycle chain of a cellphone goes beyond manufacturers, who are the producers and potential end-of-life recyclers, and includes waste management companies, recyclers, regulators, and many other stakeholders. How then can eco-conscious consumers, mobile phone producers, and the overall public help reverse this trend of e-waste piling up by the millions of tons per year?

Question

Reflect on your own cellphone use. How long have you had your current phone? What motivates (or would motivate) you to change phones? Given the option of repairing your current phone or replacing the phone when it no longer functions, what option do you prefer and why?

Problem

E-waste and its environmental impacts are problems that a safety standard can solve. In the case of electronic waste, the first sustainability standard for electronics was published in 2006, titled IEEE 1680.1, the Standard for Environmental and Social Responsibility Assessment of Computers and Displays.

At first, manufacturers struggled to become certified to IEEE 1680.1 but soon met the gold certification rating at a much higher rate, with more than 2,000 registered products reaching gold status by 2011.8 The need for manufacturers and standards technical professionals to work together is greater than ever before, and a willingness for manufacturers to seek certification of their products to meet sustainability standards is critical for preventing environmental damage. Some actions a cellphone manufacturer could take to be more sustainable and reduce e-waste include the following:

- Using recycled materials in their packaging and products

- Encouraging individuals to have their electronics professionally repaired instead of purchasing new phones and recycling or trashing their old ones

- Reusing recycled materials to build new phones

- Keeping raw materials out of landfills

- Discouraging the need for harvesting new materials from the earth

According to Proctor, 9 manufacturers have sought the highest profit margins, which led to users being restricted from having their devices repaired, but Apple has recently reversed this decision and is encouraging users to have their mobile phones repaired.10 Because of Apple’s actions and leadership, more manufacturers may see value in adopting strategies that lead to decreasing e-waste generation. Additionally, if the public was made more aware of sustainability standards that hold manufacturers to a transparent measurement, the issue of e-waste will become more front and center in the conversations around mobile phones. Companies may become incentivized to consider the sustainability of their products and adopt practices that increase profit while also reducing e-waste.

Question

The ability of users to have their devices repaired without reprisal from the manufacturer is commonly called the “Right to Repair.”

The movement claims that users have authority over the devices they purchase and should be allowed to legally have their own devices repaired. This movement has definitive benefits and trade-offs for all stakeholders.

Why would manufacturers historically be against these actions? Apple is now embracing the Right to Repair. What motivations would encourage a corporate giant such as Apple to decide to switch philosophies? What safety risks or trade-offs are present when users can repair their devices powered by lithium-ion batteries?

Approach

Building off the efforts of prior electronic sustainability standards (e.g., IEEE 1680.1, IEEE 1680.2, IEEE 1680.3), UL Standards & Engagement sought to create a sustainability standard specifically for mobile phones to counteract the volume of e-waste generated by these devices. ULSE creates standards by engaging with highly diverse professionals who think carefully about what to include in the technical document through consensus-driven technical committees.

The first technical committee (TC) of UL 110, the Standard for Sustainability for Mobile Phones, included 25 people, representing various interest categories and organizations, including the following:

- Apple

- Motorola

- Samsung

- Blackberry

- Dell

- LG

- HP

- Intel

- AT&T

- Best Buy

- UL Solutions

- UL Standards & Engagement

- U.S. Department of Energy

- U.S. Environmental Protection Agency

Building from a first draft, the TC went through a series of commenting and revision stages before voting on the first edition of the standard. Many standards allow manufacturers to reach different levels of certification, and UL 110 follows this pattern by allowing mobile phone producers to be “certified” or “platinum,” based on their achievements toward sustainability. Some key considerations included in the standard cover the following topics:

- Supply chain management of materials

- The sustainable use of raw materials (including plastics, bio-based content, and postconsumer recycled content)

- Energy use limits

- Substances of concern

- Life cycle assessment

- End-of-life management (including recyclability and repairability based on battery removal, data erasure management, and consistent plastic being used throughout the device)

- Recyclability of packaging (by incorporating recycled fibers, recycled plastics, and environmentally preferable paperboard packaging)

- Corporate sustainability

Eventually, through multiple rounds of open comments (during which anyone can submit comments for the TC to consider and vote on), and changes in the TC (members from Google and FOXCONN joined, while several U.S. government and major corporate representatives left, including LG and Blackberry), the first edition of UL 110, the Standard for Sustainability for Mobile Phones, was published in 2011. While a few of these TC members are no longer voting members, some are still involved in the standards development process and continue to provide comments and proposals for further editions of the standard. In 2017, the second edition of the standard was published, and as of 2024 the third edition is currently being worked on by the TC and ULSE. Some proposed changes to the standard help ensure the standard maintains industrywide rigorous standards towards increasing sustainability, such as adding optional criteria of eliminating cadmium and beryllium in mobile phones and required criteria that all conflict minerals (3TG) be sustainable and ethically sourced.

Question

There are a wide variety of individuals representing many organizations and industries on the technical committee for UL 110. What are the pros and cons of having diverse interest groups on this TC? What would motivate different interest groups to join this specific TC?

Solution

The first edition of UL 110, the Standard for Sustainability for Mobile Phones, contained a rigorous series of criteria for mobile phone manufacturers to obtain basic certification or platinum certification. The standard assigns point values (of various amounts) based on the sustainability criteria illustrated in the prior section.

If a manufacturer achieved 55% of the available points, the device is certified, but if the device received 73% of the available points, the manufacturer will achieve platinum certification. Back in 2013, Friedman11 reported Samsung achieving platinum certification for its Galaxy S4 — many more devices have also obtained platinum certification. The standard itself has both required criteria and optional criteria that boost the score. The more recent second version modifies this achievement criteria to bronze, silver, and gold levels of certification. To reach the bronze achievement, manufacturers must hit all required criteria; to reach silver, they must hit all required criteria, as well as 50% of the available optional points; and to reach gold, they must hit all required criteria, along with 75% of the available optional points.

One required criterion involves the substances of concern that make up the materials of the phone. Materials in the phone and battery, such as cadmium, mercury, lead, and other metals and organic substances that are susceptible to leaching into the environment and causing harm, are restricted from exceeding a maximum concentration value (MCV) set by the European Restriction of Hazardous Substances (RoHS) Directive 2002/96/EC. The following MCVs are indicated in UL 110:

- Cadmium: 100 parts per million (ppm)

- Mercury: 1,000 ppm

- Lead: 1,000 ppm

- Hexavalent chromium (which is a known carcinogen12): 1,000 ppm

- Polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE): 1,000 ppm

- Nickel release rate from the phone’s exterior: 0.5 micrograms per cubic centimeter of surface area per week

Batteries are required to be able to be removed at the end of the phone’s lifespan by qualified repair service providers or authorized repair providers; they may also be removed by users if the batteries are designed to be removable and replaceable by the user without the use of any tools as an optional requirement. This provides benefits for the sustainability of the raw materials required to create new batteries and helps consumers avoid replacing the entire phone when they only need to replace the battery.

For the phone’s packaging, neither expanded polystyrene packaging (Styrofoam is a trademarked brand of this material), nor heavy metals more than 100 ppm total may be used. Finally, all manufacturers must disclose their corporate environmental health and safety statements for anyone to see, whether this is on a website, an annual report, a sustainability report, or other dissemination source. Optional requirements allow a manufacturer to boost its score to achieve certification or platinum certification. An example of an optional achievement is the manufacturer conducting a Life Cycle Assessment of its product in alignment with ISO 14040, a standard that provides frameworks for understanding the environmental impacts of a product’s entire life cycle. For UL 110, a manufacturer needs to provide a statement of impact for how its product impacts global warming, ocean acidification, eutrophication, ozone depletion, photochemical smog formation, and primary energy demand. Organizations can go one step further in this analysis by having an independent peer review of their Life Cycle Assessments, and by addressing the results of these assessments into their corporate sustainability plans.

Repairability is a significant section in which manufacturers can earn additional points toward certification. If manufacturers offer take-back and/or refurbishment programs, they earn two points, and if they exceed certain levels of recycling rates, they earn increasingly more points, up to five points if 90% or more of the phones are recycled. If manufacturers offer replacement parts, they earn a point, and if the enclosure is easy to open, they earn one more point. If users can erase their data easily, another point is earned.

If recyclable fiber or postconsumer recycled plastic is used for packaging materials, increasing points are earned based on the amount of recycled content in the final packaging. If materials used in packaging are environmentally preferable (for example, using paper/paperboard certified by the Forest Stewardship Council, is one way to earn points), an increasing number of points are earned based on how much of the final weight is made up of the material.

Discussion Questions

- There are currently no federal laws regulating e-waste, but there are 25 states (and D.C.) that have their own programs and laws. What role could the federal government play in supporting sustainable efforts in this specific mobile phone industry? What role could consumers play in this sphere?

- What potential economic and environmental benefits would be provided by increasing the circularity of mobile phones?

- UL 110 specifically covers mobile phones, yet these devices are not the only contributors to the global concern of e-waste. Where should further sustainability efforts be placed to reduce e-waste?

A standard is a critical tool for ensuring global problems are addressed through iterative, collaborative problem-solving.

This is just a small recap, and you are encouraged to view the standard, in full, for free, by creating an account at ShopULStandards.com and using the Digital View feature.

How to get involved

Share your expertise

UL Standards & Engagement is actively seeking all interested parties to participate in its standards development process and encourages diverse perspectives to join in by participating as a stakeholder. Stakeholders can submit, review, and comment on proposals for new standards or revisions to existing standards. While stakeholders do not vote, the TC considers their input during the standards voting process. Since standards affect everyone, all are welcome to participate as stakeholders. Register online through ULSE’s Collaborative Standards Development System.

Advance your career

Check out current internship and fellowship openings for opportunities to engage with standards professionals and to contribute to standards research and innovation.

Glossary

- Circular economy

A production model that keeps materials and products in use for as long as possible through sustainability practices such as reuse, refurbishment, remanufacture, and recycling.

- Conflict minerals

Metals, including tantalum, tin, tungsten, and gold (also referenced elsewhere as 3TG), extracted from regions considered conflict-affected or high risk.

- European Union (EU) hazard classification

The EU’s system of classification, labeling and packaging chemical substances and mixtures. The Classification, Labeling and Packaging (CLP) Regulation incorporates the classification criteria and labeling rules agreed upon at the United Nations level in the Globally Harmonized System of Classification and Labeling of Chemicals (GHS).

- Eutrophication

A process by which excess amounts of nutrients, particularly nitrogen and phosphorus, accumulate in bodies of water and cause increased plant and algal growth, which can negatively impact water quality and biodiversity.

- Global warming

The rapid rise of Earth’s average surface temperature caused by increasing concentrations of greenhouse gases in the atmosphere, primarily due to human activities such as burning fossil fuels; also known as an indicator of climate change.

- Life cycle assessment

Compilation and evaluation of the inputs, outputs and the potential environmental impacts of a product system throughout its life cycle. (Reprinted from Environmental management – Vocabulary, ISO 14050).

- Ocean acidification

A series of chemical reactions that occur when excess carbon dioxide is absorbed into seawater, eventually causing the seawater pH to decrease and become acidic.

- Ozone depletion

The thinning of the stratospheric ozone layer due to chlorine and bromine containing compounds (e.g., chlorofluorocarbons, CFCs) destroying ozone molecules. Negative effects include increased ultraviolet radiation reaching Earth’s surface.

- Postconsumer recycled content

Material used by an end user which is no longer being used for its intended purpose.

- Recycled content

The proportion of preconsumer and/or postconsumer recycled material, by mass, in a product or packaging.

- Waste

Material that does not possess characteristics or meet technical specifications for use in the marketplace without further processing and will be discarded or released to the environment.

References

- Sidoti, O., Gelles-Watnick, R., Faverio, M., Atske, S., Radde, K., & Park, E. (2024, Nov 13). Mobile fact sheet. Pew Research Center. https://www.pewresearch.org/internet/fact-sheet/mobile/

- Laricchia, F. (2023, August 31). Replacement cycle length of smartphones in the United States 2013-2027, in years. Statista. https://www.statista.com/statistics/619788/average-smartphone-life/

- WEEE Forum (2022, October 13). International E-waste Day: Of ~16 billion mobile phones possessed worldwide, ~5.3 billion will become waste in 2022. WEEE Forum. https://weee-forum.org/ws_news/of-16-billion-mobile-phones-possessed-worldwide-5-3-billion-will-become-waste-in-2022/

- Lee, P., Calugar-Pop, C., Bucaille, A., & Raviprakash, S. (2021, Dec1). Making smartphones sustainable: Live long and greener. Deloitte Insights. https://www2.deloitte.com/us/en/insights/industry/technology/technology-media-and-telecom-predictions/2022/environmental-impact-smartphones.html

- Michael, C., & Sugumar, R. (2013). Studies on Leaching of Heavy Metals from E-waste. Oriental Journal of Chemistry, 29(03), 1149–1154.

- Gill, V. (2022, October 14). E-waste: Five billion phones to be thrown away in 2022. BBC https://www.bbc.com/news/science-environment-63245150

- Steves, D. (2013, Sept 17). How are E-waste laws working? Not so well, researchers say. OPB. https://www.opb.org/news/article/how-are-e-waste-laws-working-not-so-well-researche/

- Schaffer, M. (2017). Electronics standards are in need of repair: Manufacturers have weakened U.S. green electronics standards by resisting repair criteria. repair.org. https://www.repair.org/standards/

- Proctor, N. (2018, December 11). Americans toss 151 million phones a year. What if we could repair them instead? WBUR. https://www.wbur.org/cognoscenti/2018/12/11/right-to-repair-nathan-proctor

- Harding, S. (2023, August 24). Hell freezes over as Apple supports right-to-repair bill. Ars Technica. https://arstechnica.com/gadgets/2023/08/hell-freezes-over-as-apple-supports-right-to-repair-bill/

- Friedman, A. (2013, April 21). UL gives Samsung Galaxy S4 Platinum certification. PhoneArena. https://www.phonearena.com/news/UL-gives-Samsung-Galaxy-S4-Platinum-certification_id42176

- Holmes, A. L., Wise, S. S., & Wise, J. P. (2008). Carcinogenicity of hexavalent chromium. The Indian Journal of Medical Research, 128(4), 353–372. https://pubmed.ncbi.nlm.nih.gov/19106434